What is Best Practice Motor Management?

Gains Electric Motor Reliability & Returns Energy Savings.

Mark Gurney, 3phi Reliability

Why implement Best Practice Motor Management?

Nearly ALL facilities operations are driven by Electric Motors and most are a single point of failure, meaning a single Motor irrespective of size can bring the Profit Making ability to it’s knees.

While electric motors are inherently very robust a number of factors can greatly shorten the service life, even a very low failure rate causes significant Downtime due to the shear numbers in any facility.

What is often forgotten is an Electric Motor running continuously will use Approximately 16 times it purchase value each year in Energy and that cost can rank as the Number One in the Operational Budget.

What should you Expect from a Motor? Failure Rates of electric motors vary a lot due to Manufacturing Defects, Transport/Storage, Installation, Sizing, Environmental, and Power Supply Quality to name a few, but get these right and the expected failure rate should be well below 3%. That’s a 30 year service life, unfortunately many facilities are getting a 5 year service life and some motors only lasting months.

Sealed Bearings are so called Sealed for Life, but this life is only limited to the grease depletion. Once the lubrication film is lost the Bearings decay quickly and account for more than half of Motor failures. Changing to Polyurea thickeners return service life extension of approximately 5x.

Acceptance Testing is essential to stop defects entering your facility, once a motor is taken off the delivery truck IT’S YOURS FOR LIFE.

A surprising high number of New & Overhauled Motors don’t meet a standard Motor Test.

Concepts of Motor Management?

Best Practice Motor Management has been developed from Decades of Reliability Work, and addresses the Failure Modes of Electric Motors from Sizing, Purchase, Storage, Installation, Environmental, and Basic Care. These proven strategies consistently eliminate 90%+ of Electric Motor Failures.

How to Implement Best Practice Motor Management? Implementation https://www.3phi-reliability.com/services

Test & Collect Name Plate Data, Inspections, Sizing (Loading),

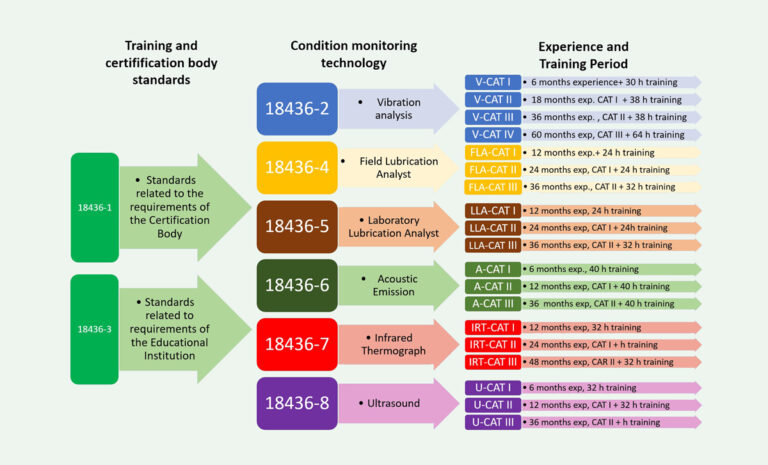

Test methods include VA, Ultrasonics, Motor Circuit Analysis, Current, Earth Resistance and Inverter Emissions.

A mobile App Developed by 3Phi Reliability Collects Motor Data, aiding Lubrication Schedules, Vibration Analysis, and Ultrasonic Analysis but more importantly builds an Asset Database for Implementing Best Practice Motor Management.

Remedial Work/ Document Energy Savings/ IEC rating

During the Test & Collect Phase remedial work is conducted to restore circuit resistances gaining immediate Energy Savings. As Found and As Left measurements document these savings.

Criticality Analysis 1 2 3

Many facilities may have already assessed criticality and 3Phi Reliability recommended a three level definition based on Single Point of Failure, and consequences of failure including Safety, Environmental, and Loss of Profit.

Match Motor Health to Criticality Response time (Access, Lifting, Lead Times) Risk Profile all play a part in response times. A motor in a difficult position can add days to replacement adding Safety and cost factors.

Once Motor Health is Quantified (Remaining Life Estimator can be used as a guideline) this is matched to Criticality and the exposes the Facility Risk Profile.

Installation Practice Alignment/Balancing/Terminations can quickly decay components in an electric Motor. Assessment of the total circuit often identifies defects that cause Voltage drop, which is a major factor in Motor Winding life.

3Phi Reliability provide Hands On coaching in Electric Motor Installation practice.

FMECA Electrical Preventative Maintenance & Basic Care

Every facility has unique mix of factors that contribute to Electric Motor Decay, some being Environmental, Installation Practice, Bearing Selection, etc.

During the Testing & Inspection phase these potential failure modes are documented and included in the Failure Modes & Effects, Criticality Analysis and the ultimate output is a Asset Plan that addresses the facility’s requirements.

Note: A cookie cutter approach to Preventative Maintenance often misses failure modes, and can bloat tasks which really don’t add much value.

Spares Assessment

The Steps to this point expose the Risk Profile of the Motor Assets, and therefore determines what should be Stocked, Held at a Vendor, or Known Lead Times required.

Very few facilities have a spares assessment and if attempted is often incomplete or made on estimates. Many existing motor spares aren’t matched to an Asset, and this makes selection when a failure occurs stressful to the technician and extends Downtime

Opportunities to upgrade to a higher efficiency motor can not be made until Motor Details, Loading, Run Hours, Spares Inventory, and Spares “Fit for Use” have been assessed.

Test for “Fit for Use”

Many Motor held as Spares aren’t in a condition that can be relied on. Until a Motor Test, and details collected to determine the condition or “Fit for Use” a motor can not be Passed fit.

Missing Links, Broken Terminal Boxes, Seized Bearings, Broken Feet, Winding Defects, Rotor Defects, and Poor Terminations are common problems.

Purchase Spec/Overhaul Specification

The decision to Overhaul a motor must be made with sound reliability principles. Many factors determine a good Overhaul or Purchase, decisions made solely on price don’t end well. Example Fake Bearings are Cheap for a Reason.

Purchasing different Brands often means different Grease Nipples and Grease types won’t match site requirements risking a compounding problem because of price.

3Phi Reliability have proforma Purchase & Overhaul Specifications for Clients.

Spares Strategy

If you enterprise is multi site you have an opportunity to share Spares but this requires Best Practice Motor Management principles across sites.

If you are small facility your commercial leverage is limited, but approaching a single vendor with Motor Management in mind can be add value to your strategy.

Rationalization of Spares

As Electric Motors can take sizeable portion of Maintenance Spares in value it is often questioned by commercial colleagues and without documented spares strategy risk being lost.

Rationalizing spares and offering redundant assets as a piece offering can help especially if those spares are needed at a different site.

Motor Storage/Transport

The only reason an Electric Motor Spare is held is to reduce Response Time when it is needed.

That means it should be able to be accessed, identified, and relied upon to work.

If your store is disorganized, takes hours of pallet movements to get to the back of the store, motors have sucked in moisture, or damage has occurred.

3Phi Reliability recommend 5S principles to reduce response time, and should be part of the Spares Strategy.

https://www.3phi-reliability.com/blog/best-practice-in-electric-motor-storage

Summary: Electric Motors are the drivers of your facility, consume most of your Energy and most likely a good proportion of the Maintenance activities.

Best Practice Motor Management is a proven strategy to lower the total cost of ownership.

3Phi Reliability offer Remote Coaching Globally in Best Practice Motor Management.